New Technology

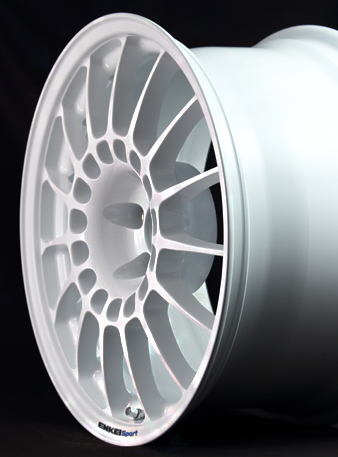

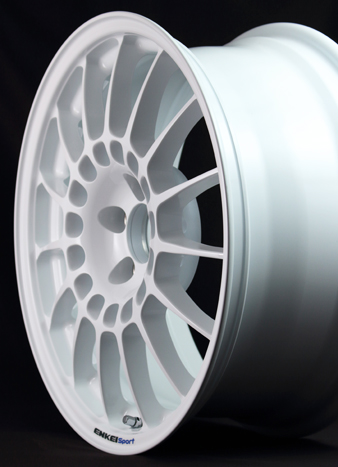

MAT RIM-FORMING PROCESS

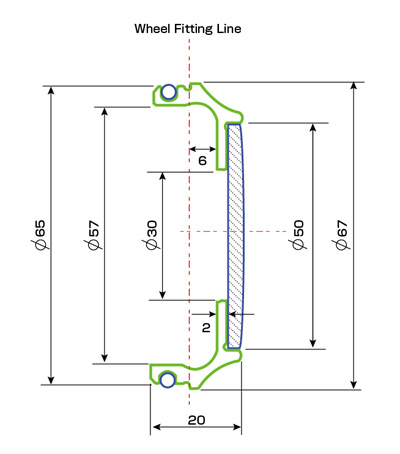

The Most Advanced Technology combines one-piece cast wheel technology with a rim forming technology called spinning process.

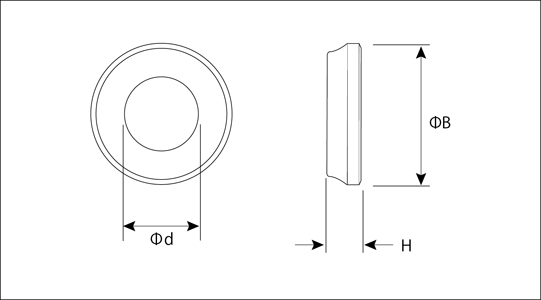

The Most Advanced Technology combines one-piece cast wheel technology with a rim forming technology called spinning process.After casting, the rim part of wheel is forged and elongated while rotating (See the diagram above).

This process allows a fiber flow in the rim part, which resembles the property obtained from forging process.

The result is, strengthen rim like forged, with complex face design unlike forged.